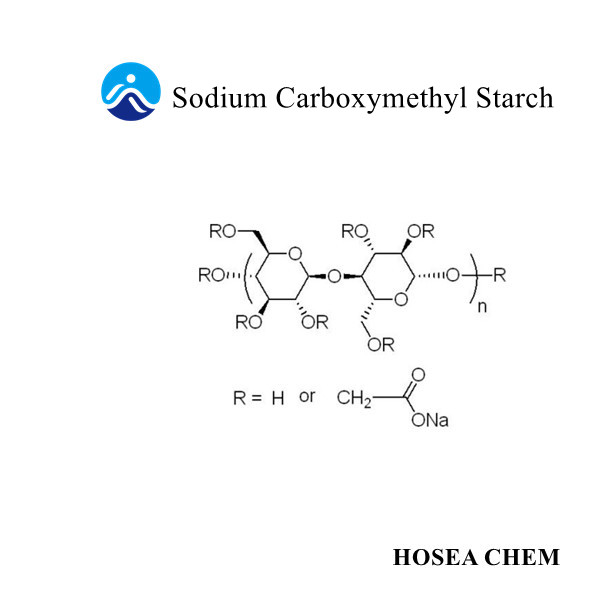

Usage and contraindications of sodium carboxymethyl cellulose

2022-07-191. The sodium carboxymethyl cellulose is directly mixed with water and prepared into a paste-like glue for use.

When configuring sodium carboxymethyl cellulose paste, first add a certain amount of clean water to the batching tank with a stirring device, and when the stirring device is turned on, slowly and evenly sprinkle sodium carboxymethyl cellulose on the In the batching tank, keep stirring, so that the sodium carboxymethyl cellulose and water are completely fused, and the sodium carboxymethyl cellulose can be fully dissolved. When dissolving sodium carboxymethyl cellulose, the reason for evenly spreading it and stirring constantly is to "prevent the occurrence of agglomeration, agglomeration, and reduction of carboxymethyl cellulose when sodium carboxymethyl cellulose meets water. The problem of the amount of sodium dissolved" and improve the dissolution rate of sodium carboxymethyl cellulose. The stirring time is not the same as the time for the sodium carboxymethyl cellulose to dissolve completely. They are two concepts. Generally speaking, the stirring time is much shorter than the time required for the sodium carboxymethyl cellulose to completely dissolve. The time required depends on the specific situation.

The basis for determining the stirring time is: when the sodium carboxymethyl cellulose is uniformly dispersed in the water and there are no obvious large lumps, the stirring can be stopped, and the sodium carboxymethyl cellulose and water can be left standing. Infiltrate and merge with each other.

The basis for determining the time required for complete dissolution of sodium carboxymethyl cellulose is as follows:

(1) Sodium carboxymethyl cellulose and water are completely bonded, and there is no solid-liquid separation between the two;

(2) The mixed paste is in a uniform state, and the surface is smooth and smooth;

(3) The color of the mixed paste is close to colorless and transparent, and there are no granular objects in the paste. It takes 10 to 20 hours from when the sodium carboxymethyl cellulose is put into the batching tank and mixed with water until the sodium carboxymethyl cellulose is completely dissolved.

2. The sodium carboxymethyl cellulose is first mixed with dry raw materials such as white granulated sugar in the form of a dry method, and then dissolved in water.

During operation, put sodium carboxymethyl cellulose and white sugar and other dry raw materials in a certain proportion in a stainless steel mixer, close the top cover of the mixer, and keep the materials in the mixer in a sealed state. Next, turn on the mixer and thoroughly mix the sodium carboxymethyl cellulose and other raw materials. Then, slowly and evenly sprinkle the mixed sodium carboxymethyl cellulose mixture into the batching tank filled with water, and keep stirring, and the subsequent operation can be carried out with reference to the above-mentioned first dissolving method.

When using sodium carboxymethyl cellulose in liquid or slurry food, it is best to homogenize the mixture to achieve a more delicate tissue state and stabilization effect. The pressure and temperature used in the homogenization should be determined according to the characteristics of the material and the quality requirements of the product. After the sodium carboxymethyl cellulose is prepared into an aqueous solution, it is best to store it in ceramic, glass, plastic, wooden and other types of containers, and it is not suitable to use metal containers, especially iron, aluminum and copper containers.

Because, if the sodium carboxymethyl cellulose aqueous solution is in contact with the metal container for a long time, it is easy to cause the problems of deterioration and viscosity reduction. When the aqueous solution of sodium carboxymethyl cellulose coexists with lead, iron, tin, silver, aluminum, copper and some metal substances, a precipitation reaction will occur, reducing the actual quantity and quality of sodium carboxymethyl cellulose in the solution.

If it is not required for production, try not to mix calcium, magnesium, salt and other substances into the sodium carboxymethyl cellulose aqueous solution. Because the coexistence of sodium carboxymethyl cellulose aqueous solution and calcium, magnesium, salt and other substances will reduce the viscosity of sodium carboxymethyl cellulose solution. The prepared sodium carboxymethyl cellulose aqueous solution should be used up as soon as possible. If the aqueous solution of sodium carboxymethyl cellulose is stored for a long time, it will not only affect the adhesive properties and stability of sodium carboxymethyl cellulose, but also suffer from microorganisms and insects, thus affecting the hygienic quality of raw materials.