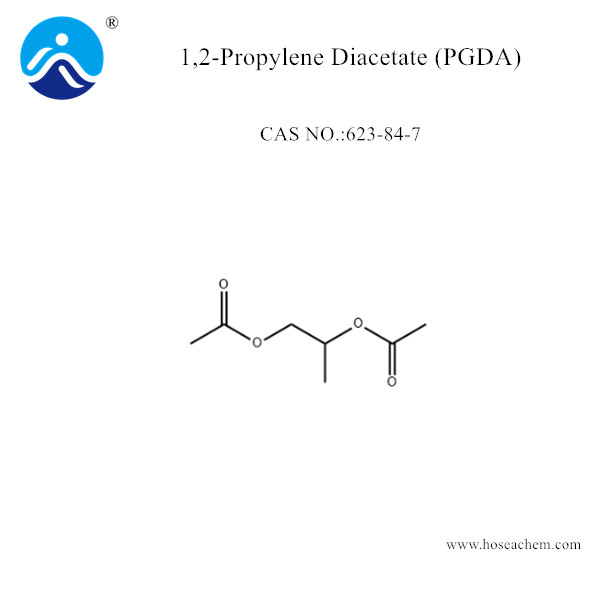

1,2-Propylene Diacetate (PGDA)

Hosea Chem® has been supplying 1,2-Propylene Diacetate (PGDA) (CAS 623-84-7) with high quality and competitive price for many years, covering most of the European, American, etc. Send Inquiry

Product Description

1,2-Propylene Diacetate

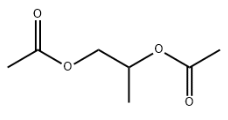

Chemical Name:1,2-Propylene Diacetate;PGDA;CAS 623-84-7

EINECS No.: 210-817-6

Chemical Formula: C7H12O4

Molecular Weight: 160.17

Melting point: -31°C

Boiling point: 191℃

Flash point: 187°F

Density at 25°C: 1.05 g/mL

Molecular Structure:

Description

1, 2-propylene glycol diacetate is a colorless to light yellow liquid with low volatility and a slight sweet taste. It is soluble in organic solvents such as alcohols and ethers, but insoluble in water. PGDA is a functional environmentally friendly solvent with the general chemical properties of esters. Easy to dissolve in alcohol, ether and other organic solvents, with excellent leveling, low odor, safety and non-toxic, strong solubility, good bubble inhibition, strong dispersion of pigments. It has the advantages of anti-floating color, anti-white paint film, anti-heat rash, etc. It is an efficient, environmentally friendly and functional organic solvent.

1,2-Propylene Diacetate Standard

Appearance: Colourless to light yellow liquid

Content %≥: 99.0

Density at 25°C: 1.05 g/mL

Vapor pressure (20℃): <1 hPa

Refractive index n20/D: 1.414

Explosive limit %(v): 2.8-12.7

Acid Number: ≤0.015

Application

1,2-Propyleneglycol diacetate (PGDA) is a versatile solvent with a wide range of applications due to its favorable properties such as a high boiling point, low toxicity, and environmental friendliness. Here are some of the primary applications of PGDA:

Application Area | Use of PGDA | Function/Benefit |

Ink and Adhesive | Replacement for various solvents in inks and adhesives | PGDA replaces isophorone 783, CAC, ethylene glycol monobutyl ether, propylene glycol ether ester solvents, cyclohexanone, diacetone alcohol (DAA), cresol, etc., due to its environmental safety and solvency. |

Coating Film Additives | In can/coil coatings and as a film forming agent | Combines the properties of CAC, PMA, BCS, and CYC. Offers environmental friendliness, low odor, good leveling, and strong solubility. Enhances safety in storage and production due to high flash point. Improves gloss, fullness, and whiteness in topcoat paints. Prevents heat rash and dark bubble formation. |

Water-based Curing Agents | As a diluent in water-based PU curing agents | Exhibits strong hydrophobicity and poor reactivity with NCO, enhancing fluidity and fullness of the film, and improves thickness of the non-foaming film. |

Diluent for Various Resins | Replacing DBE as a solvent for multiple resins | Superior solubility compared to DBE. Effective in dissolving alkyd, acrylic, polyester, nitrocellulose, and chloro-acetate resins. Offers high boiling point, narrow distillation range, low-odor, and environmental protection. |

Industrial Cleaning Agents | As a solvent in industrial cleaning | Effective in cleaning electronic and precision equipment |

Pharmaceuticals | Solvent for active ingredients | Non-toxic and safe for use in sensitive applications |

Cosmetics | In cosmetic formulations | Ensures safety and efficacy of cosmetic products |

Food Industry | In flavor extracts and food additives | Safe for use in food-related applications |

Resin Synthesis | For water-based resin synthesis | Enhances resin properties, useful in various industrial products |

Electronics | In PCB circuit board ink and electronic ink | Improves print quality and durability on circuit boards |

Cleaning and Paint Removal | Used as a cleaning agent and paint remover | Effective in removing paints and cleaning surfaces |

Plastics Industry | Cellulose acetate plasticizer | Improves flexibility and durability of plastic products |

Organic Synthesis | As an intermediate | Used in the synthesis of various organic compounds |

The wide-ranging applications of PGDA in various industries underscore its importance as a solvent and an agent that enhances the performance of products in coatings, inks, adhesives, and more. Its growing popularity is also partly due to the increasing focus on environmentally friendly and safer chemical products in industrial processes.

Three Generations of High Boiling Point Environmental Solvent Comparison

| Generation | Solvent Type | Key Characteristics | Applications |

|---|---|---|---|

| First | Organic Dibasic Acid Ester Mixtures | Can completely or partially replace solvents like cyclohexanone, ethylene glycol ether acetate, etc. Improves coating leveling and adjusts drying speed. | Used in steel, wood, container, food packaging, automobile coatings, enameled wire coatings, and baking paints. |

| Second | Ethylene Glycol Diacetate(EGDA) | More environmentally friendly than the first generation. Offers similar replacement functions for high-boiling point odor solvents. | Suitable for baking paint, nitrocellulose paint, coil steel paint, cellulose ester, fluorescent paint, iron printing paint, automotive paint, wood paint, insulation paint, and electrical appliances and metal furniture paint. |

Third | 1,2-Propylene Diacetate (PGDA) | Strong solubility, non-toxic, low odor, and more environmentally friendly than the first and second generations. | Ideal for alkyd resin, acrylic resin, polyester resin, nitrocotton resin, chlorinated resin, and PU curing agents. Functions as a superposition of the first two generations’ solvents. |

Storge & Handling

Stored in a cool, dry, and well-ventilated area, away from direct sunlight, heat sources, and incompatible materials. It is important to keep the container tightly closed when not in use.

Packing

200KG/Drum