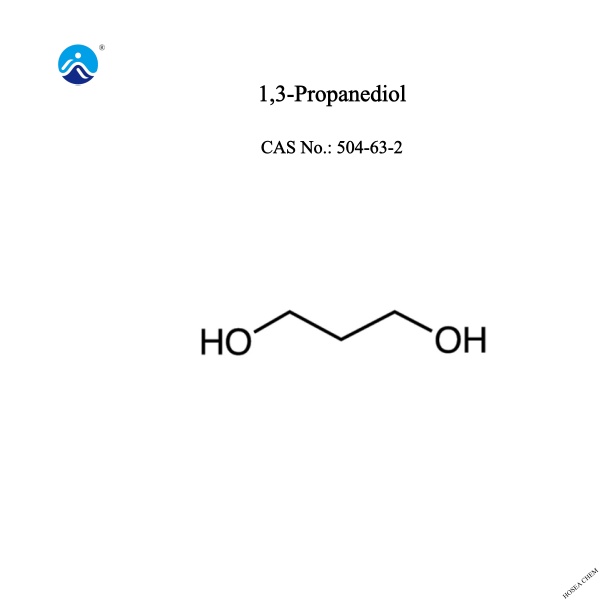

1,3-Propanediol

Hosea Chem® has been supplying 1,3-Propanediol (CAS 504-63-2) (1,3-Dihydroxypropane) with high quality and competitive price for many years, covering most of the European, American, middle east, etc. Send Inquiry

Product Description

1,3-Propanediol (PDO)

1,3-Propanediol utilizes native Shell technology, with an annual production capacity of 72,000 MT, and uses ethylene oxide as a raw material. Compared to bio-fermentation processes using glucose and glycerol, the ethylene oxide method offers a more stable production process, fewer impurities, lower costs, higher product purity, and stronger batch stability, making it suitable for high-end polyester synthesis.

As a key monomer in PTT polymerization, 1,3-Propanediol significantly improves the elasticity, softness, and stain resistance of materials, and is widely used in high-performance fibers and engineering plastics. Furthermore, its excellent moisturizing properties make it suitable as a humectant in cosmetics. The company also uses bioethanol to produce syngas, enabling the production of bio-based PDO to meet the needs of diverse customer groups.

Specification of Product

Product Name : 1,3-Propanediol

1,3-Dihydroxypropane

Trimethylene Glycol

PDO

![]()

CAS No.: 504-63-2

EINECS No.: 207-997-3

Molecular Formula: C3H8O2

Molecular Weight: 76.10

1,3-Propanediol Technical indicators

Appearance: Colorless transparent liquid with no visible impurities

Purity, %: ≥99.5

Moisture,%: ≤0.5

Chroma (Pt-Co), %: ≤10

UV absorbance (270nm): ≤0.250

Burning residue, %: ≤0.001

Iron (Fe), %: ≤ 0.0005

1,3-Propanediol Packaging

1000kg/IBC,20MT/20’FCL

1,3-Propanediol Applications

1,3-Propanediol is used in the production of PTT polyester (polypropylene terephthalate), cosmetics (moisturizers), pharmaceuticals, polyurethanes, etc.