Heat Reactive Phenolic Resin

Hosea Chem® has been supplying Heat Reactive Phenolic Resin with high quality and competitive price for many years, covering most of the European, American, etc. Send Inquiry

Product Description

Heat Reactive Phenolic Resin

Vulcanizing Resin HO1045

Application

Heat Reactive Phenolic Resin is a heat-reactive phenolic resin with hydroxymethyl groups on both sides.

Heat Reactive Phenolic Resin is primarily used as a vulcanizing resin for butyl rubber, nitrile rubber, CR, NR, or EPDM.

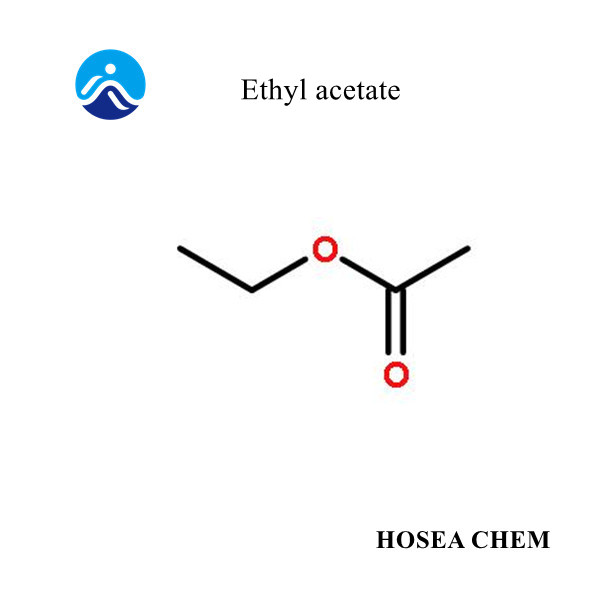

Heat Reactive Phenolic Resin is soluble in aromatic and aliphatic solvents such as toluene, xylene, and ethane.

Core types: Amberol ST-137, SP-1045, and Hi2501.

Heat Reactive Phenolic Resin (Vulcanizing Resin HO1045) exhibits heat resistance, high pressure resistance, and aging resistance, and can be added directly into the mixing process. It is primarily used in airbag products, medical butyl rubber products, seals, and hoses.

Quality indicators

Appearance: Light yellow block or granule flaky

Softening point, ℃: 85-95

Ash (% at 800°C/2h): ≤1.0

Hydroxymethyl content, %: 8-12

Density,°C: 1.04

Packaging and storage

25Kgs/ paper polyed bag, stored at room temperature, dry, and out of direct sunlight for one year without affecting the product.