Selection principle of sodium carboxymethyl cellulose CMC for ceramic glaze

2022-01-241. Determine the viscosity of sodium carboxymethyl cellulose according to the glaze formula

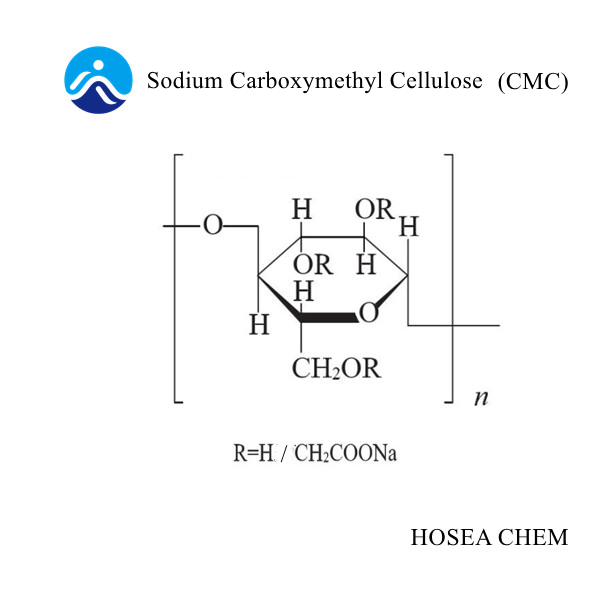

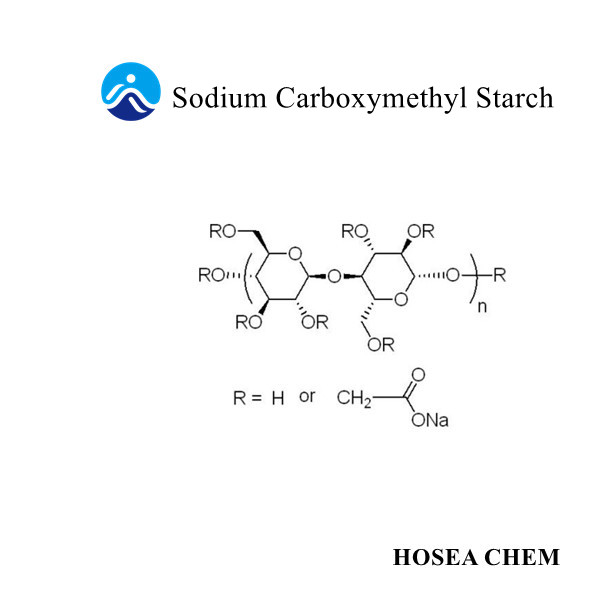

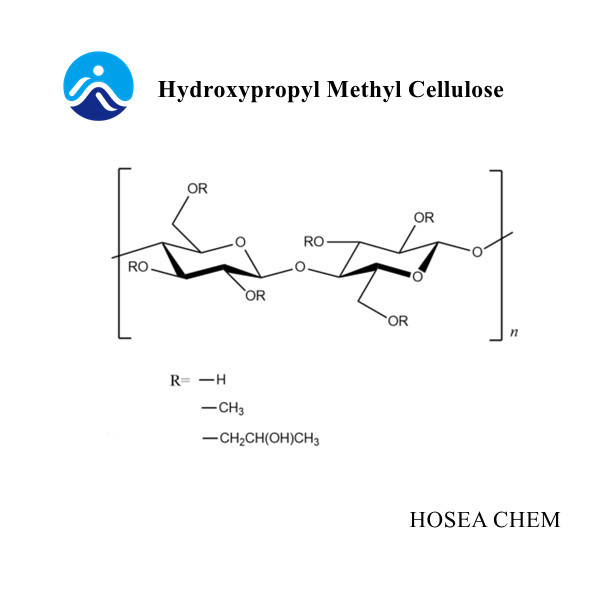

The raw materials used in the glaze mainly include feldspar, quartz, dolomite, calcium carbonate, aluminum hydroxide, pickling powder, zinc oxide and kaolin, etc. The raw materials used vary slightly according to the color tone. However, it is mainly based on barren raw materials, and the amount of plastic raw materials is generally less than 10%. Some formulas do not use plastic kaolin raw materials. In this way, the viscosity of the glaze slurry is mainly adjusted by adding sodium carboxymethyl cellulose CMC. In the ceramic slurry, medium and high viscosity sodium carboxymethyl cellulose is usually selected.

2. Selection of degree of substitution of sodium carboxymethyl cellulose

In the production of glaze paste, we have noticed a phenomenon: when the fineness of the glaze paste is detected, CMC particles can be seen on the screen, and the performance of the glaze paste is greatly affected. This is related to ignoring or inappropriate degree of substitution of CMC.

The degree of substitution is a key factor that determines the water solubility of sodium carboxymethyl cellulose. With the increase of the degree of substitution, the water solubility of CMC increases. The amount of CMC in the ceramic glaze is small, but good solubility is required, and the degree of substitution is usually ≥ 0.7.

In addition, CMC should be selected with high purity, without color magazines, and can be burnt out to ensure that the glaze surface of the product is clean after firing. Ceramic manufacturers can use the method of quality assessment to ensure the quality of the CMC used.