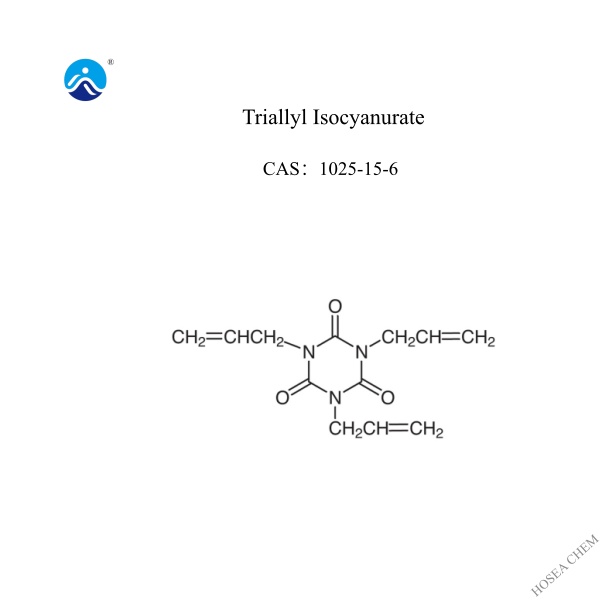

Triallyl Isocyanurate

Hosea Chem® has been supplying Triallyl Isocyanurate (Cas 1025-15-6) with high quality and competitive price for many years, covering most of the European, American, etc. Send Inquiry

Product Description

Triallyl Isocyanurate

This product exhibits excellent stability at room temperature and can be stored at room temperature for extended periods. Due to its three allyl groups, TAIC possesses the general properties of aliphatic olefins, such as various addition reactions, homopolymerization, and copolymerization. When heated to above 140°C in air, it undergoes self-polymerization, becoming a transparent, rigid homopolymer.

Specification of Product

Product Name : Triallyl Isocyanurate

TAIC

Molecular Formula: C12H15N3O3

Cas No.: 1025-15-6

Physical Properties:

Appearance: Colorless liquid or hexagonal crystals at room temperature

Molecular Weight: 249.27

Specific Gravity: 1.155 (30℃)

Melting Point: 24℃ (pure product), 17-21℃ (industrial product)

Viscosity: 83 ± 3 centipoise (30℃)

Boiling Point: 144℃/3mmHg, 297℃/N2, 760mmHg

Flash Point: 355℃

Specific Heat: 0.6 (40℃)

Solubility: Soluble in aromatic hydrocarbons, halogenated hydrocarbons, cycloalkanes, acetone, various alcohols, etc.; slightly soluble in alkanes; insoluble in water.

Triallyl Isocyanurate Quality Standard

Type AB-S AB-Ⅰ AB-Ⅱ

Appearance : Colorless transparent oily liquid or crystals Transparent oily liquid or crystals Slightly yellow oily liquid or crystals

Content (GC), %≥ : 99.0 98.0 95.0

Acidity %≤ : 0.2 0.3 0.5

Chroma, (Pt-Co) ≤ : 30 50 150

Packing: 200Kg/Drum 200Kg/Drum 200Kg/Drum

Type AB-P AB-E

Appearance : White powder White powder

Content (GC), %≥ : TAIC(68.5-71.5) TAIC(48.5-51.5)

Acidity %≤ : N/A N/A

Chroma, (Pt-Co) ≤ : N/A N/A

Packing: 25Kg/Bag 25Kg/Bag

Triallyl Isocyanurate Applications

1. A crosslinking modifier for various thermoplastics (polyethylene, polyvinyl chloride, chlorinated polyethylene, EVA, polystyrene, etc.). The typical addition amount for thermal crosslinking is 1-3%. Dicumyl peroxide (DCP) can be added at 0.2-1%. For irradiation crosslinking, the addition amount is 0.5-2%, and DCP may not be necessary. Crosslinking significantly improves the heat resistance, flame retardancy, solvent resistance, mechanical strength, and electrical properties of the products. It significantly improves product quality compared to using a peroxide system alone and is odorless. Typical applications include polyethylene, polyethylene/chlorinated polyethylene, polyethylene/EVA crosslinked cables, and high- and low-foaming polyethylene products.

2. A vulcanizing aid for ethylene propylene rubber, various fluororubbers, CPE, and other specialty rubbers (used in conjunction with DCP, typically at 0.5-4%). It significantly shortens vulcanization time and improves strength, abrasion resistance, solvent resistance, and corrosion resistance.

3. Crosslinking agents for acrylic and styrene-based ion exchange resins. Compared to divinylbenzene crosslinking agents, these require less dosage, produce higher quality resins, and can be used to prepare ion exchange resins with excellent anti-fouling, high strength, large pores, heat resistance, acid and alkali resistance, and oxidation resistance. This is a newly developed and promising type of ion exchange resin both domestically and internationally.

4. Modifiers for polyacrylates, polyalkyl acrylates, etc., can significantly improve heat resistance, optical properties, and processing performance. Typical applications include heat-resistant modification of ordinary acrylic glass.

5. Modifiers for epoxy resins and DAP (diallyl phthalate) resins can improve heat resistance, adhesion, mechanical strength, and dimensional stability. Typical applications include modification of epoxy potting compounds and encapsulants.

6. Crosslinking agents and modifiers for unsaturated polyesters and thermoplastic polyesters can significantly improve heat resistance, chemical corrosion resistance, dimensional stability, weather resistance, and mechanical properties. Typical applications include increasing the service temperature of hot-pressed unsaturated polyester fiberglass products to above 180℃.

7. TAIC's homopolymer, poly(triallyl isotrimer), is a transparent resin with excellent hardness, heat resistance, and electrical insulation, used for bonding glass and ceramics. It is typically used in the manufacture of multilayer safety glass.

8. TAIC 850, through emulsion graft copolymerization with acrylic acid, styrene, acrylonitrile, etc., can be used to prepare excellent impact modifiers for thermoplastics such as PVC and PS, and can also directly prepare molding plastics with excellent impact resistance.

9. TAIC is a heat-resistant, radiation-resistant, and weather-resistant protective agent for metals. When TAIC prepolymer is baked onto metal surfaces, the resulting film exhibits excellent heat resistance, radiation resistance, weather resistance, and electrical insulation. It is typically used in the manufacture of insulating materials for printed circuit boards and other components in microelectronic products.

10. TAIC is an intermediate in the production of UV-curable coatings, photoresists, flame retardants, and flame-retardant crosslinking agents. It is typically used in the synthesis of the highly efficient flame retardant TBC and the flame-retardant crosslinking agent DABC.