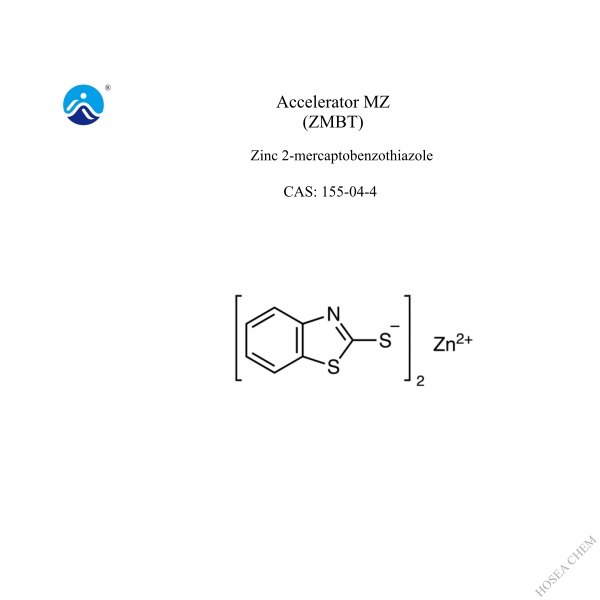

Zinc 2-mercaptobenzothiazole

Hosea Chem® has been supplying Zinc 2-mercaptobenzothiazole (Accelerator MZ) with high quality and competitive price for many years, covering most of the European, American, etc. Send Inquiry

Product Description

Zinc 2-mercaptobenzothiazole

Specification of Product

Product Name : Accelerator MZ (Accelerator ZMBT)

Chemical Name: Zinc 2-mercaptobenzothiazole

Cas No.: 155-04-4

Molecular formula: C14H8N2S4Zn

Accelerator MZ [ Zinc 2-mercaptobenzothiazole ] Physical Data

Appearance Light yellow powder

At the beginning of melting point / ℃ ≥ 200

Heating reduction, % ≤ 0.50

The zinc content, % 15.0-18.0

Free M, % 3

Sieve residue (120 m),% ≤ 0.02

Accelerator MZ [ Zinc 2-mercaptobenzothiazole ] Properties

Light yellow powder (granules), slightly bitter, non-toxic. Specific gravity: 1.70, decomposition temperature: 300°C.

It is soluble in chloroform and acetone, partially soluble in benzene, ethanol and carbon tetrachloride, and insoluble in gasoline, water and ethyl acetate.

Storage stable. Decomposes in strong acid or alkaline solutions.

Packaging, transportation, and storage

Package:25kg/Bag

This product should be stored in a dry, light-proof indoor warehouse to prevent moisture.

During the storage, transportation and loading and unloading of this product, avoid rain; avoid direct sunlight; ensure that it is dry and the packaging bag is not damaged or contaminated by other items; do not mix or store with toxic or harmful items; do not store at high temperatures.

Accelerator MZ [ Zinc 2-mercaptobenzothiazole ] Applications

Zinc 2-mercaptobenzothiazole is a high-speed vulcanization accelerator that does not stain rubber.

Zinc 2-mercaptobenzothiazole is suitable for NR, IR, BR, SBR, NBR, EPDM, and latex.

When used on dry rubber, it exhibits performance similar to WILLING MBT with excellent scorch resistance.

Accelerator MZ exhibits mild activity in latex systems and is often used in combination with super accelerators.

Accelerator MZ has a high critical vulcanization temperature (138°C).

Accelerator MZ is less susceptible to premature vulcanization and exhibits a wide vulcanization profile.

It can adjust the viscosity of latex systems.

It is suitable for injection molding and foam rubber products. It is safe to operate, easy to disperse, non-staining, and non-discoloring.

It is resistant to aging when used in combination with TP.

It is primarily used in the manufacture of general industrial products such as tires, hoses, rubber shoes, and rubber tape.