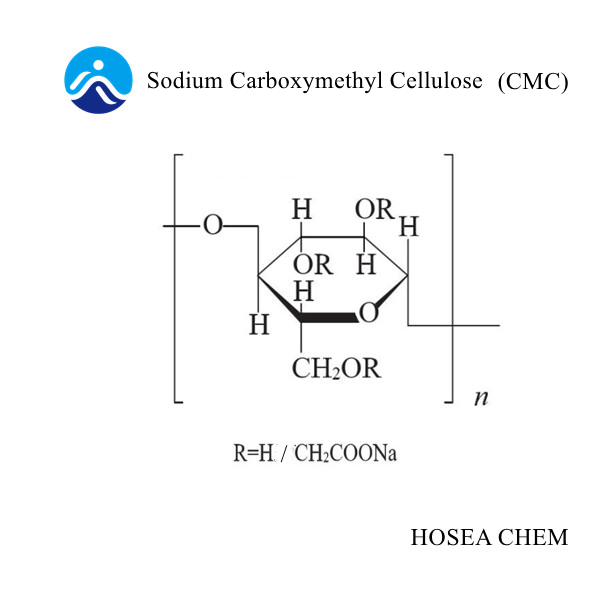

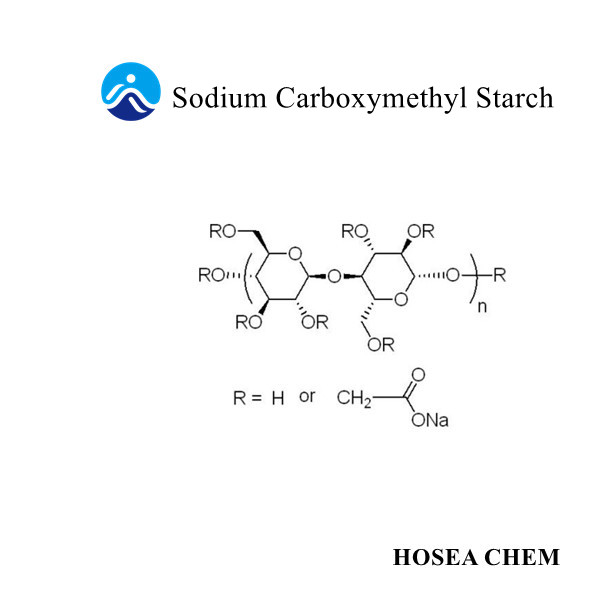

The addition amount of sodium carboxymethyl cellulose CMC in the ceramic glaze

2022-01-24The amount of sodium carboxymethyl cellulose CMC added affects its concentration in the glaze slurry, and the viscosity of the glaze slurry increases with the increase of the amount of CMC added.

The principle for determining the amount of addition is:

1.Determine the amount of CMC added according to the glaze formula. The content of plastic raw materials in the glaze is high, and the amount of CMC added is small, on the contrary, the amount of CMC added is large.

2. Determined according to the glaze slurry process parameters. For glaze paste with strong adhesion and slow drying speed, the amount of CMC added should be higher, and vice versa.

3. Determined by using CMC viscosity. When the viscosity of CMC is high, the addition amount is small, and when the viscosity is low, the addition amount is large.

4. Determine the added amount according to the experimental results.

Generally, the low viscosity sodium carboxymethyl cellulose CMC is added in an amount of 0.2-0.5%;

Medium viscosity and high viscosity sodium carboxymethyl cellulose CMC is added in an amount of 0.1-0.3%.

In addition, the amount of CMC added varies with the seasons. When the temperature is high in summer, the viscosity of CMC solution decreases with the increase of temperature, so the amount of CMC added in summer should be appropriately increased compared with other seasons. In the rainy season, the air humidity is high, the surface of the embryo body is moist, and the drying is slow. Therefore, the drying speed of the glaze slurry should be increased, and the amount of CMC added should also be appropriately reduced.